one. Product Features

Walnut shell filter is a kind of filtering equipment suitable for oily sewage treatment. The equipment uses walnut shells with strong adsorption capacity, strong pressure resistance, stable chemical properties, high hardness, good hydrophilicity, oil resistance and special processing as the filter material. Its biggest feature is that the filter material is backwashed and regenerated Convenient, it can be directly used for backwashing with pre-filtered water, without air source and chemical agents.

two. Scope of application

1. It is suitable for the filtration treatment of oily wastewater and other oily wastewater recycling systems in the steel, metallurgical and coal industries;

2. It is suitable for the fine filtration of the reinjection water of the large-volume oilfield, the water produced by the offshore oil platform, and the treatment of the recycled water of the thermal recovery boiler in the heavy oil oilfield;

3. It is suitable for filtration treatment and advanced treatment of cooling circulating water in power plants, oil refineries and petrochemical plants.

three. Features

Anti-oil immersion, double-effect removal of oil and suspended matter, strong adsorption, large dirt interception; easy to regenerate, backwashing and dosing are optional.

Four. technical parameter

1. Treatment effect

2. Working environment parameters

①. Working temperature: 5-60℃ (special temperature can be customized);

②. Working pressure: ≤0.6MPa;

③. Inlet water pressure: ≥0.04MPa;

④. Backwash water inlet pressure: ≥0.15 MPa;

⑤. Pressure difference between inlet and outlet: 0.1-0.2MPa.

3. Operating parameters

①. Working method: pressure type;

②. Operation mode: water flow from top to bottom;

③. Filtration speed: 20-25m/h;

④. Operating cycle: 8-24h;

⑤. Backwashing method: air-water combined backwashing;

⑥. Water consumption for backwashing: 1-3%;

⑦. Backwash intensity: 4-15l/s·m2;

⑧. Backwash duration: 20-30min;

⑨. Backwash expansion rate: 30-50%.

five. working principle

The filter is a separation equipment successfully developed using the principle of filtration and separation. It uses an oil-resistant filter material—a special walnut shell as the filter medium. The walnut shell has the characteristics of large specific surface area, strong adsorption force, and large dirt interception to remove oil and water in the water. Suspended matter. The equipment has two control modes: automatic and manual. When filtering, the water flows from top to bottom, through the water distributor, filter layer, and water collector to complete the filtration. When backwashing, the agitator overturns the filter material, and the water flows from bottom to top, so that the filter material can be thoroughly cleaned and regenerated.

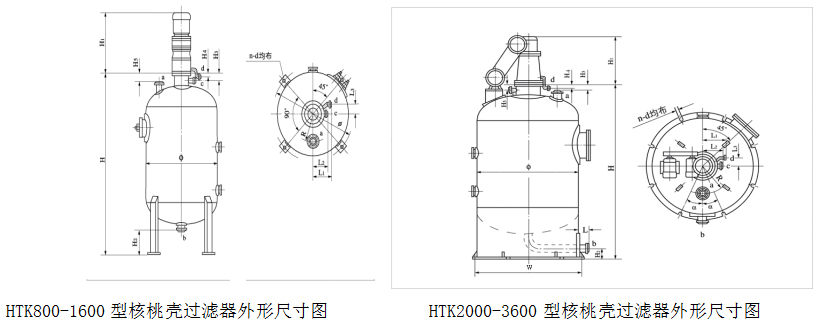

six. Specifications and dimensions

1. Dimensions

2. List of specifications and models

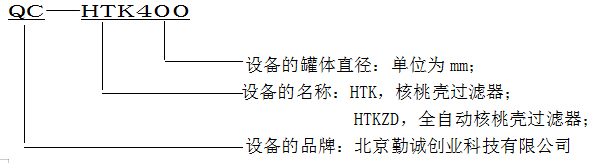

3. Model Description

- Previous Article: Fiber bundle filter

- Next Article: Quartz sand filter