As crude oil becomes heavier, the quality of raw materials used in various hydrogenation processes is getting worse and worse, and the content of metal impurities and solid salt particles is high. These impurities are easy to deposit on the top of the reactor when they pass through the hydrogenation reactor. It is difficult for the materials to pass, which causes the pressure drop of the reactor to increase and is forced to skim the head for processing.

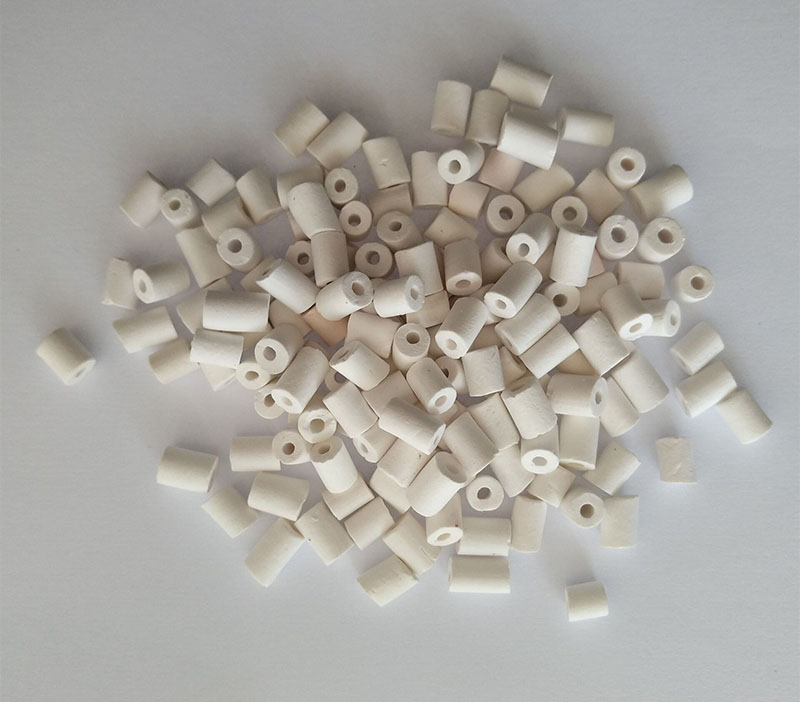

It is based on solving these problems that the series of hydrogenation protective agents produced by our factory are AL2O. It is a carrier with a certain active component. It has: ①large porosity, low internal diffusion resistance, high metal-tolerant deposition ability; ②moderate specific surface area, large pore volume, large pore size, and high demetallization Features such as activity and moderate desulfurization activity. The series of hydrogenation protective agents can effectively remove various metal impurities and other solid particles in the oil, and appropriately hydrogenate the easily coking substances in the raw oil to slow down the poisoning and coking of the main catalyst, and avoid the deposition of various metals and solid particles. At the top of the reactor.

>>Product Usage

Used as a protective layer catalyst for diesel hydrofining, paraffin wax hydrofining, microcrystalline wax hydrofining, lubricating oil hydrotreating and supplementary refining, heavy oil hydrocracking, hydrofining and coking wax oil, etc. The hydrogenation protective agent can effectively prolong the service life of the main catalyst and delay the rising speed of the catalyst bed pressure drop, thereby prolonging the operation period of the device.

>>Product normal use conditions

Operating temperature: 320-450C

Operating pressure: <1 5Mpa

Liquid space velocity: <7h-1

Hydrogen to oil ratio (volume): ≥150

- Previous Article: Activated carbon

- Next Article: Iron removal catalyst