The metal orifice double-wave corrugated packing is assembled on the surface of the metal sheet by perforating, rolling small grains, large corrugations, and secondary corrugations. It has small resistance and uniform gas-liquid distribution, high efficiency, large flux, and insignificant amplification effect, etc. Features, applied to negative pressure, normal pressure and pressurized operation. The effect of using metal orifice plate corrugated packing to transform the plate tower is particularly obvious. The tower diameter range for processing packing is Φ150mm-12000 mm or more.

A. Product features:

The packing maintains the structural characteristics of the metal wire mesh corrugated packing, and is made of an orifice plate with grooves on the surface, which increases the uniform distribution of the liquid and the wetting performance of the packing, and improves the mass transfer efficiency. The height of each disc unit is 50-200mm, the diameter is more than 1.5m, and the packing is made into blocks.

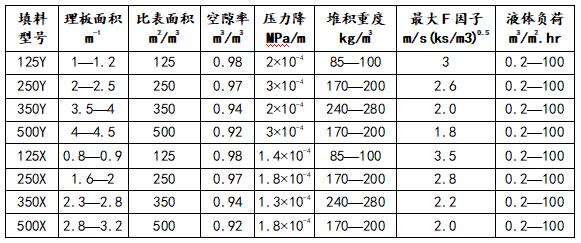

B. Characteristic data:

The metal orifice corrugated packing has the advantages of large flux, low resistance, high efficiency and strong anti-blocking ability. It is widely used in unit operations such as distillation, absorption and extraction. According to the packing model, the smallest tower is 80-200mm, the largest diameter has reached 13m, the liquid spray density can be from 0.2 to 200m3/(m2.h), and the pressure range can be from vacuum to high pressure. Most suitable for general-purpose high-efficiency structured packing in chemical, fertilizer, oil refining, petrochemical, natural gas and other industries.

- Previous Article: Stainless steel wire mesh demister, demister

- Next Article: Metal corrugated structured packing