Polytetrafluoroethylene abbreviated as F4 (PTFE), commonly known as the king of plastics, is the best-performing plastic material in the world today. It has excellent corrosion resistance, except for fluorine at high temperature and alkali metals and trifluoride in molten state. In addition to chlorine, it can almost resist the corrosion of various chemicals on the earth; good electrical insulation, and its products can withstand voltages of more than 15,000 volts per millimeter of thickness; good oxidation resistance, even in the earth environment for decades Aging; good temperature resistance, can work normally at -180-250C; its surface friction coefficient is very low, and has the rare advantage of non-scaling on the surface; it does not absorb water, and is widely used in petroleum , Pharmacy, chemical industry, metallurgy, textile, electronics, electrical appliances, machinery, dyes, food, electricity, water treatment, environmental protection, aviation, military, scientific research and papermaking and other industries have a wide range of uses.

Polytetrafluoroethylene abbreviated as F4 (PTFE), commonly known as the king of plastics, is the best-performing plastic material in the world today. It has excellent corrosion resistance, except for fluorine at high temperature and alkali metals and trifluoride in molten state. In addition to chlorine, it can almost resist the corrosion of various chemicals on the earth; good electrical insulation, and its products can withstand voltages of more than 15,000 volts per millimeter of thickness; good oxidation resistance, even in the earth environment for decades Aging; good temperature resistance, can work normally at -180-250C; its surface friction coefficient is very low, and has the rare advantage of non-scaling on the surface; it does not absorb water, and is widely used in petroleum , Pharmacy, chemical industry, metallurgy, textile, electronics, electrical appliances, machinery, dyes, food, electricity, water treatment, environmental protection, aviation, military, scientific research and papermaking and other industries have a wide range of uses.

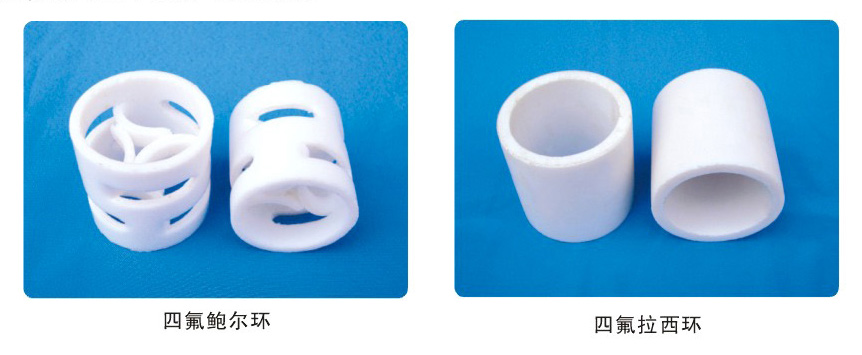

Tetrafluoro ring

The Raschig ring is the earliest ring packing in the history of tower packing, with a fixed geometric shape. Its characteristics are: the diameter and height of the packing ring are equal, and the structure is simple and inexpensive.

PTFE Pall ring (strengthened Pall ring)

PTFE Pall ring packing has the advantages of large flux, low resistance, high separation efficiency and large operating flexibility. Under the same pressure reduction, the processing capacity can be more than 50% larger than that of the Raschig ring. The pressure can be reduced by half, and the mass transfer efficiency can be increased by about 20%. Compared with the Raschig ring, this packing has the characteristics of large production capacity, strong resistance, and large operating flexibility. Under normal circumstances, the treatment can be 50-100% larger than the Raschig ring at the same pressure drop. In the same treatment, the pressure drop is 7-50% smaller than that of the Raschig ring, and the tower height is also reduced. The use of the Pall ring can be about 20-40% of the packing volume than the Raschig ring. Tetrafluoro Pall ring packing is a new type of packing, which is developed to improve some of the main shortcomings of Raschig rings. It is to open six layers of small rectangular windows on the wall of ordinary Raschig rings, and the small window blades are in the center of the ring. The upper and lower windows are intertwined with each other. The main difference between it and the Raschig ring packing is that there are rectangular window holes on the side wall, and the window leaves of the window holes are bent into the ring center. It is suitable for various separation, absorption, desorption equipment, atmospheric and vacuum equipment, synthetic ammonia decarbonization, desulfurization system, ethylbenzene separation, isooctane, toluene separation, etc.

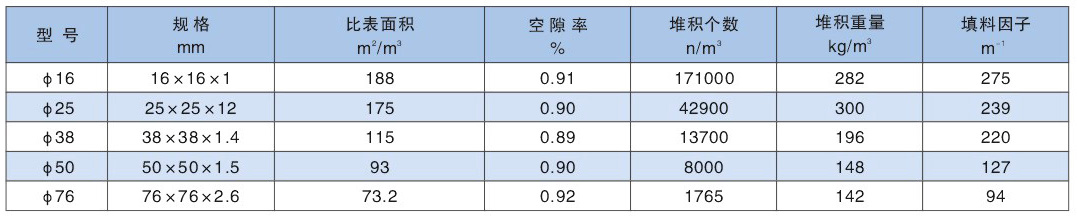

Main technical indicators of PTFE Pall ring

- Previous Article: Plastic structured packing

- Next Article: PTFE coalescing and separating inner parts (PTFE)