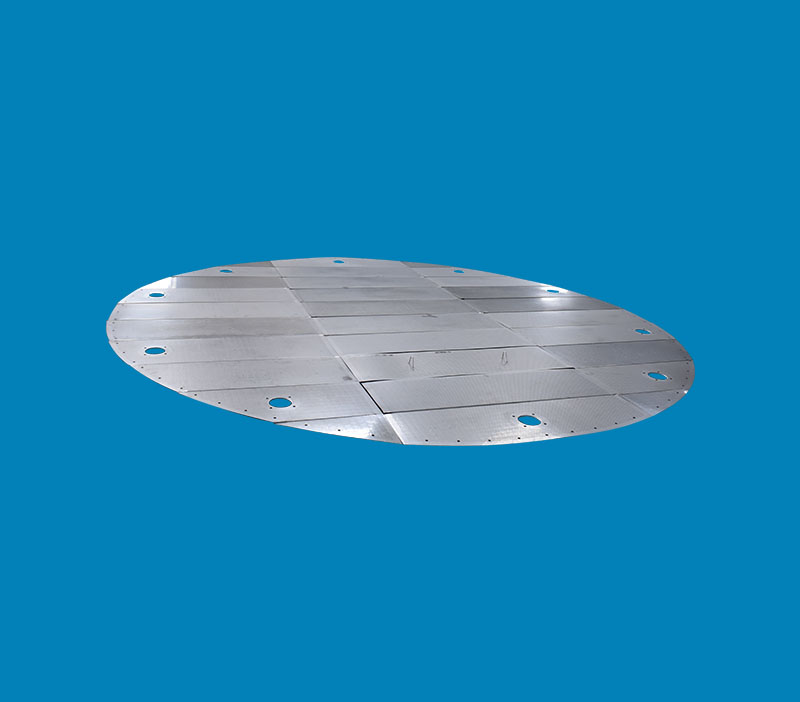

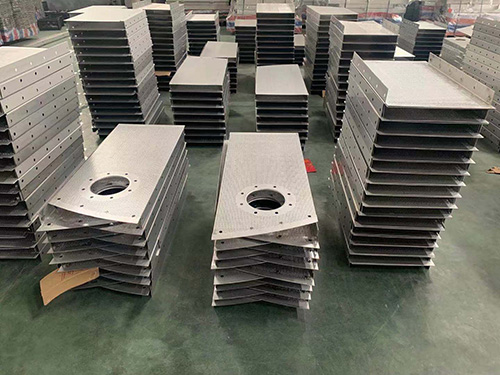

Product model: DN600-DN10000 can be produced according to requirements

The sieve tray is made with many small holes on the tray. During operation, the liquid flows in from the downcomer of the upper tray. After flowing through the sieve tray laterally, it passes over the overflow weir and is led to the lower tray through the downcomer; Pass through the sieve holes from bottom to top, and disperse into bubbles to pass through the liquid layer. In this process, mass and heat transfer are carried out. Since the gas passing through the sieve has kinetic energy, the liquid will not leak from the sieve in a large amount under normal circumstances.

The small hole diameter of the sieve tray is an important parameter, the smaller the airflow distribution is more uniform, the operation is more stable, but the processing is difficult and easy to block. At present, the commonly used aperture of industrial sieve trays is 2-8mm. The ratio of the total area of the sieve openings to the area of the openings is called the opening rate, which is another important parameter. Under the same empty tower speed, if the opening rate is large, the hole speed is small, which is easy to cause liquid leakage and reduce efficiency, but the mist entrainment is also reduced; if the opening rate is too small, the tray resistance is large, which is easy to cause large mist entrainment And liquid flooding limits the production capacity of the tower. Usually the open porosity is 5-15%. The sieve holes are generally arranged in an equilateral triangle, and the ratio of the hole spacing to the hole diameter is usually 2.5-5.It has the following characteristics:

(1) The structure is simple, the manufacture is convenient, the maintenance is convenient, and the cost is low.

(2) The pressure drop on the tray is small.

(3) Large processing capacity, 20-40% higher than bubble tower.

(4) The efficiency of the tray is 15% higher than that of the bubble tower, but slightly lower than that of the valve tray.

(5) The elasticity is small, and the sieve holes are easy to be blocked.

- Previous Article: Float valve tray

- Next Article: Tongue and floating tongue tray