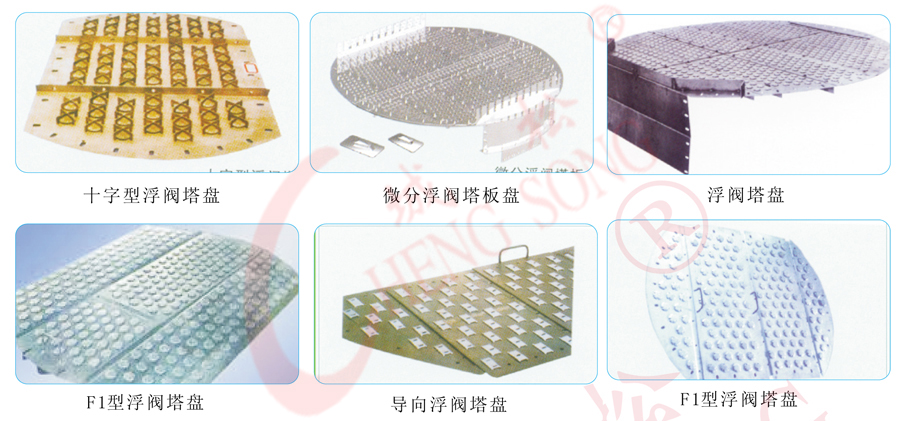

Product model: DN600-DN10000 can be produced according to requirements

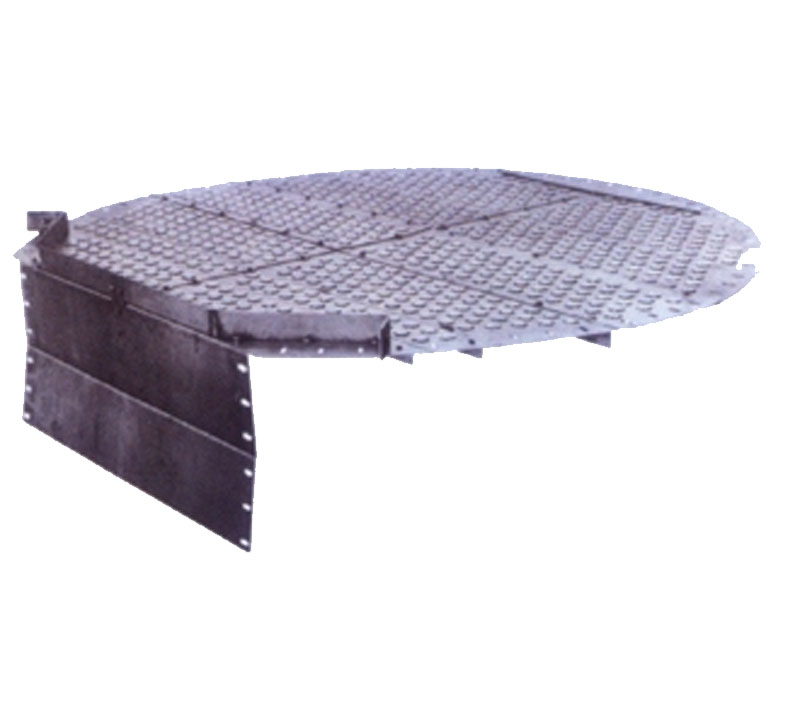

The float valve tray is a tray with many round holes, and each hole is equipped with a valve with three legs that can float up and down. Float valves are components that ensure gas-liquid contact. The main types of float valves include F-1, V-4, A, and cross types. The most commonly used is F-1. F-1 type float valve has two kinds of light and heavy. The light valve has a thickness of 1.5mm and a weight of 25g. The light valve has small inertia, high vibration frequency, serious lag when closing the valve, and serious leakage at low gas speeds. It is suitable for treatment Large volume and small pressure drop are required. The heavy valve has a thickness of 2mm and a weight of 33g. It closes quickly and requires a higher air speed to blow open. Therefore, it can reduce leakage and increase efficiency, but the pressure drop is slightly larger. Generally, a heavy valve is used. During operation, the air flow blows up the float valve from bottom to top, and blows horizontally from the periphery of the float valve into the liquid layer on the tray; the liquid flows from the upper tray to the lower tray through the downcomer, and then flows across the tray to contact the gas phase. After quality, it enters the downcomer through the overflow weir and flows into the next layer of trays.

Comprehensive features:

(1) The processing capacity is larger, which is 20-40% higher than that of the bubble tower. This is because the air flow is sprayed horizontally, which reduces the entrainment of mist and the float valve tray can have a larger opening rate.

(2) The operating flexibility is greater than that of the bubble tower.(3) The separation efficiency is higher, about 15% higher than that of the bubble tower. Because there are no complicated obstacles on the tray, the liquid level difference is small, and the airflow on the tray is relatively uniform.

(4) The pressure drop is lower, because the gas passage is much simpler than the bubble column, so it can be used for vacuum distillation.

(5) The structure of the tray is relatively simple and easy to manufacture.

- Previous Article: Shutter type liquid collector

- Next Article: Sieve tray