Product model: DN600-DN10000 can be produced according to requirements

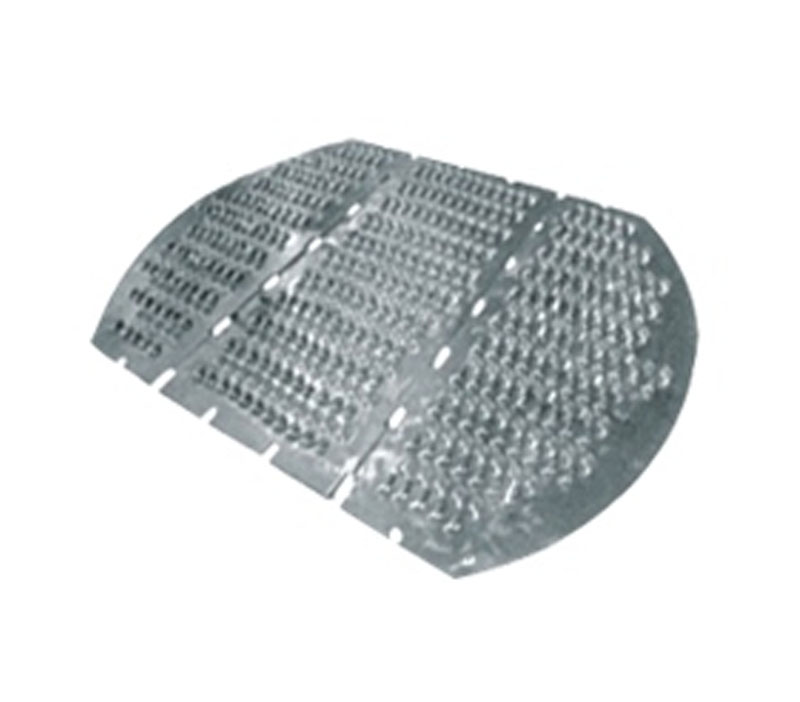

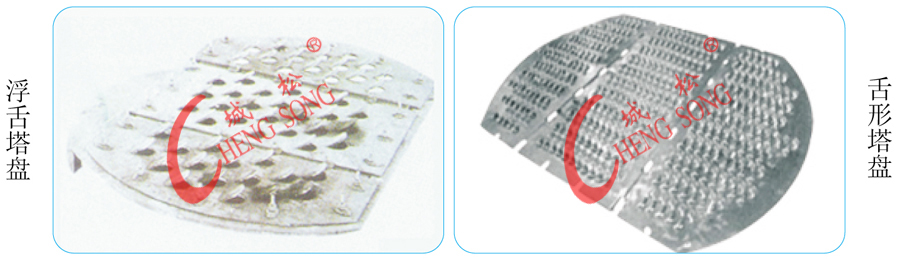

The tongue-shaped tray is a series of tongue holes punched on the tray plate, and the tongues and the tray plate have a certain inclination angle. When the gas flow passes through the tongue hole, the gas jet is used to disperse the liquid phase into droplets and stream for mass transfer, and push the liquid phase through the tray. The inclination angle between the tongue hole and the tray plate is generally 18 degrees, 20 degrees and 25 degrees, usually 20 degrees. The tongue holes are commonly used in two types: 25X25mm and 50X50mm. The tongue holes are arranged in a triangle. The tongue-shaped tray has the advantages of simple structure, convenient installation and maintenance, large processing capacity, small pressure drop, and less mist entrainment. However, because the inclination angle of the tongue hole is fixed, it is easy to cause liquid leakage when operating under low load. Operational flexibility is small. The floating tongue tower tray is a kind of tray developed by combining the advantages of the valve tower and the tongue tower. The fixed tongue of the tongue tower is changed to a floating tongue. Similar to the valve tower, the floating tongue can float up and down as the gas load changes to adjust the air flow channel area to ensure a suitable gap gas velocity and strengthen the gas and liquid Mass transfer, reduce or eliminate leakage. When the floating tongue is opened, it is the same as the tongue-shaped tray, and the gas and liquid flow in parallel, and the liquid phase is dispersed for mass transfer by the jet effect of the gas phase.

Comprehensive features:

(1) It has large operating flexibility and stable operation. Under the condition of ensuring high efficiency, its load variation range can even exceed that of the valve tower.(2) It has a large gas and liquid phase processing capacity, and the pressure drop is small, which is especially suitable for vacuum distillation.

(3) The structure is simple and the production is convenient.

(4) The efficiency is higher, between the float valve and the tongue-shaped tray, and the efficiency changes with the gas velocity slightly larger than that of the float valve.

- Previous Article: Sieve tray

- Next Article: Blister tray