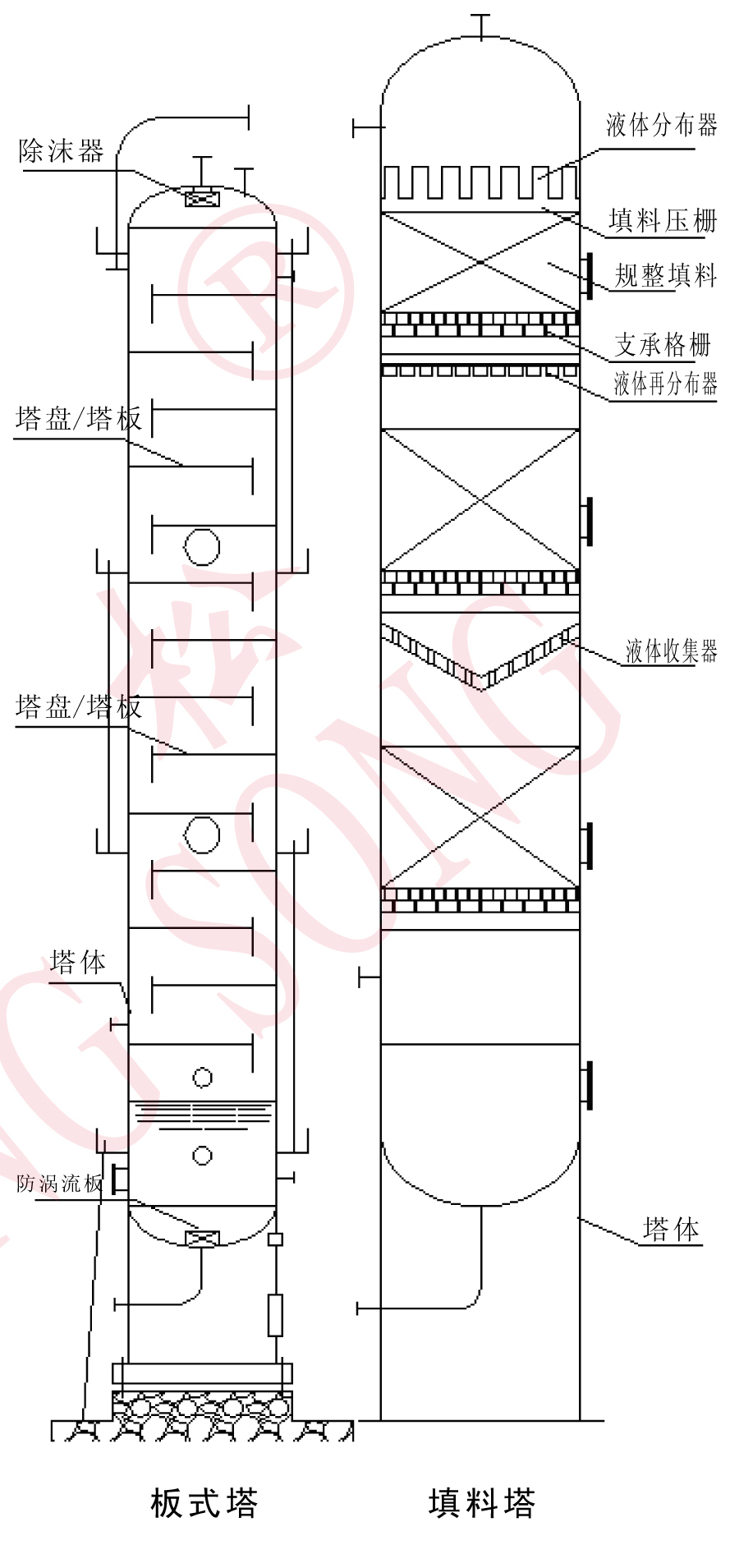

one. The internals of the plate tower

The plate tower is a hierarchical contact mass transfer equipment for gas-liquid or liquid-liquid systems. It consists of a cylindrical tower body and a number of trays that are horizontally installed in the tower at a fixed interval. Widely used in rectification and absorption, some types (such as sieve tray) are also used in extraction, and can also be used as a reactor for gas-liquid phase reaction processes. During operation (taking the gas-liquid system as an example), under the action of gravity, the liquid flows through each layer of trays from top to bottom, and then discharges to the bottom of the tower; the gas is driven by the pressure difference and passes through each layer from bottom to top. Layer trays and discharge to the top of the tower. A certain depth of liquid layer is maintained on each tray, and the gas is dispersed into the liquid layer through the trays for mutual contact and mass transfer.

Second, the internals of the packed tower

The internals of the packed tower mainly include packing support device, packing compaction device, liquid distribution device, liquid collection and redistribution device, etc. Reasonable selection and design of tower internals is very important to ensure the normal operation of the packed tower and excellent mass transfer performance.

1. Packing support device

The function of the packing supporting device is to support the packing in the tower. Commonly used packing supporting devices include grid plate type, perforated tube type, hump type and so on. The selection of the supporting device is mainly based on the tower diameter, the type and model of packing, the material of the tower body and packing, and the gas-liquid flow rate.

2. Packing compaction device

A compression device installed above the packing can prevent the packing bed from loosening and jumping under the action of airflow. Packing compaction devices are divided into two categories: packing pressure plate and bed limit plate, each of which has a different type. The packing pressure plate is freely placed on the upper end of the packing layer, and the packing is pressed tightly by its own weight. It is suitable for bulk fillers made of ceramics, graphite, etc., which are easily broken. The bed limiting plate is used for bulk packing made of metal, plastic, etc. that are not prone to breakage and all structured packing. The bed limiting plate must be fixed on the tower wall. In order not to affect the installation and use of the liquid distributor, continuous tower rings cannot be used to fix it. Small towers can be fixed to the tower wall with screws, while large towers are fixed with lugs.

3. Liquid distribution device

There are various types of liquid distribution devices, such as nozzle type, disk type, tube type, trough type and trough disk type.

The liquid is sprayed from the small holes of the hemispherical nozzle, the diameter of the small holes is 3~10mm, arranged in concentric circles, the spraying angle is ≤80°, and the diameter is (1/3~1/5)D. This kind of distributor has a simple structure and is only suitable for towers with a diameter less than 600mm. Because the small holes are easy to be blocked, it is generally used less.

Disc distributors include disc sieve distributors, disc overflow pipe distributors and other forms. The liquid is added to the distribution plate and flows down through the sieve or overflow pipe. The diameter of the distribution plate is 0.6 to 0.8 times the diameter of the tower, and this type of distributor is used in towers with D<800mm.

The tubular distributor is made of perforated tubes with different structures. Its outstanding features are simple structure, large free cross section for gas to flow through, and low resistance. However, the small holes are easy to be blocked, and the elasticity is generally small. Tubular liquid distributors are widely used, and are mostly used in packed towers with liquid loads below medium. In vacuum rectification and wire mesh corrugated packing tower, it is often used because of the small liquid load. Tubular distributors have different shapes such as row-tube type and ring-tube type. According to the liquid load, it can be made into single row or double row.

4. Liquid collection and redistribution device

When the liquid flows downward along the packing layer, there is a phenomenon that it deflects to the tower wall. This phenomenon is called wall flow. The wall flow will cause uneven gas-liquid distribution in the packing layer and reduce the mass transfer efficiency. In order to reduce the wall flow phenomenon, a liquid redistribution device can be arranged in the packing layer at a certain height. The simplest liquid redistribution device is a truncated cone redistributor. The truncated cone redistributor is simple in structure and easy to install, but it only plays the role of converging the wall flow to the center, without the function of liquid redistribution, and is generally used in towers with a diameter of less than 0.6m. Under normal circumstances, the liquid collector and the liquid distributor are generally used at the same time to form a liquid collection and redistribution device. The function of the liquid collector is to collect the liquid flowing down from the upper packing, and then send it to the liquid distributor for liquid redistribution. The commonly used liquid collector is the inclined plate liquid collector.

As mentioned above, the trough-plate liquid distributor has both the functions of liquid collection and liquid separation, so the trough-plate liquid distributor is an excellent liquid collection and redistribution device.

- Previous Article: Removable grooved disc gas-liquid distributor

- Next Article: No Record