The bio-ceramsite filter material is made of high-quality clay as the main raw material, and is processed into gray-brown spherical particles through a series of processes such as drying, batching, powdering, pelletizing, high-temperature firing, and sieving. The physical microstructure of the product is characterized by well-developed surface micropores and reasonable distribution. The average micropore diameter is about 200 microns. The microorganisms growing in the micropores are not easy to lose, so that the biological aerated filter can operate intermittently; the specific surface area is large. It can adhere to grow and multiply a large number of microorganisms, which can increase the volume load of the biological aerated filter and significantly increase the degradation rate; light texture, high strength, friction resistance, washing resistance, no release of toxic and harmful substances into the water body, and good physical , Chemical and hydraulic characteristics, can be adapted to the requirements of different sewage purification, is the preferred filter material for water treatment, especially sewage, micro-polluted source water biological pretreatment and water supply filtration technology.

>>Main features

◆Abundant surface micropores, large specific surface area, easy to hang membrane and large biomass, good removal effect on NH-N and COD, strong sewage interception ability, and high quality of treated water;

◆The pores of the filter layer are evenly distributed, and the surface pores are medium and large pores suitable for microbial growth, which overcomes the problems of large head loss, easy blockage and compaction caused by uneven pore distribution of the filter layer;

◆The density is moderate, the specific gravity is uniform, the time required for backwashing is short, the use cycle is long, and the energy consumption is low, which overcomes the defects of difficult control and easy material running, and saves electricity and labor;

◆Using good particle size grading, strong dirt holding capacity, high utilization rate of filter media, slow increase in head loss, filtration speed up to 16m/h under the same conditions, working cycle more than 24h, and cycle water production up to 800-1000m /m", 1.5-2 times that of quartz sand filter;

◆It does not contain any harmful substances to the human body and the environment, with high mechanical strength, impact resistance and abrasion resistance, and good biological and chemical stability and thermodynamic stability.

>>Scope of application

◆Industrial sewage and drinking water treatment, industrial circulating water treatment;

◆Sewage (waste) water, reclaimed water advanced treatment and reuse treatment, swimming pool water treatment;

◆Treatment of micro-pollutants (ammonia nitrogen) in water supply, high-purity preparation pretreatment system;

◆Biological carrier of biological aerated filter (BAF).

>>Physical Index

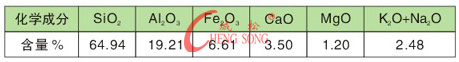

>>Chemical composition

- Previous Article: Microporous filter bricks, plates, tubes

- Next Article: Rare earth porcelain sand filter material