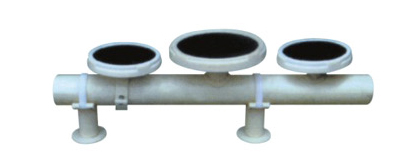

The diaphragm type microporous aerator is the latest aerator device developed by our company. The device has a small aeration bubble diameter, a large gas-liquid boundary area, uniform bubble diffusion, no clogging of holes, and strong corrosion resistance. After more than 50 users have used it for many years, the effect is good (compared to the conventional products of fixed spiral aerator, diffuse aerator and perforated tube aerator, the energy consumption is reduced by 40%, or the sewage treatment capacity is increased by 40%). It is especially suitable for urban sewage, new expansion of large factories and transformation of old aeration tanks, and the aeration tanks can be operated intermittently.

>>Main technical indicators

Aerator size: Type I D=21 5mm, Type II D=260mm

Average running pore of aeration diaphragm: 80-100 μm

Air flow: 1.5- -3m3/pch

Service area: Type I 0.25-0.5m/piece, Type II 0.35-75m2/piece

Total oxygen transfer coefficient: kla(20℃)0.204-0.337min-1

Oxygen utilization rate (water depth 3.2m): 18.4%-27.7%

Oxygenation capacity: 0.112-0.185KgO2/m3 h.

Oxygenation power efficiency: 4.46-5.19KgO2/KW. h;

Aeration resistance: 2.75Kpa.

The air pipe design should consider the pressure balance, it is best to form a ring network, and each group of intake branch pipes should be equipped with valves to facilitate the adjustment of the air volume. Air pipe design flow rate: main pipe is 10-15m/s; branch pipe is 5m/s, the installation height of the aeration pipe surface from the bottom of the pool is: I type 250mm, II type 270mm, and the push plate type is 200mm.

- Previous Article: Fiber ball filter

- Next Article: Ceramic filter