Ceramic filter, also called ceramic filter tank, is a kind of fast and high-efficiency filtration equipment. When the filter material is blocked, the system can be used to flush the filter material and restore the function of the filter equipment without affecting normal operation. This product has the advantages of automatic separation, easy installation, low land occupation, high temperature resistance, high pressure, acid and alkali corrosion resistance, high filtration accuracy, thorough and efficient recoil, long service life, reliable operation, simple maintenance, etc.; it can be widely used in petrochemical industry Solid-liquid separation, gas purification, water treatment, etc. in the fields of, metallurgy, food, brewing, and pharmaceuticals.

>>Filtering characteristics

◆High filtration efficiency: the oil removal rate is 80-95%, and the removal rate of suspended solids with a particle size of more than 5um is about 90%; the regeneration efficiency is high: the simple gas-liquid rapid recoil method can be used to efficiently remove the clogged ceramic filter element Fast regeneration and long service life;

◆Excellent resistance to chemical corrosion; resistance to various acids, alkalis, salts, most organic solvents below 70°C, odorless, non-toxic, and no foreign matter leaching; thermal stability: thermal stability of filter material 200-- 20C does not split three times;◆Filtration accuracy and filtration rate: It is related to factors such as the average pore size, wall thickness, filtration pressure difference and material parameters of the microporous medium. It can be determined correctly through experiments and calculations. It can be filtered at a filtration rate of 5-10m/s. .

>>Main purpose

◆In the field of environmental protection, filtration and dehydration of sludge and flocculants after chemical coagulation of wastewater; pretreatment of wastewater treatment by ion exchange, electrolysis, and activated carbon adsorption; filtration treatment of suspended solids in boiler wet dust removal wastewater (can be Realization of closed-circuit circulation); terminal treatment of air flotation and evaporation concentration; oil-water separation treatment of oily wastewater; various flue gas dust removal and filtration.

◆This filter is suitable for the separation of solid suspended particles and oil in liquids, especially in toxic media.

◆It can be widely used in water treatment, metallurgy, petroleum, chemical, electric power, light industry, food, medicine, textile, paper, coking and steel industries where production needs to be recycled.

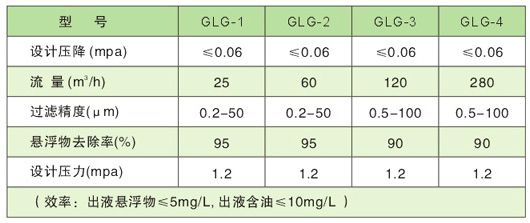

>>Technical parameters

- Previous Article: Membrane microporous aerator

- Next Article: Single hole membrane aerator