one. Product Features

The fluoride filter is mainly used to remove fluoride in the system and purify the water quality; it can also be used to decolor and deodorize the water.

two. Scope of application

It is often used as a special equipment for centralized removal of fluoride ion in drinking water that uses groundwater as a source of water. It can also be used for the treatment of fluorine-containing industrial wastewater and arsenic-containing drinking water.

three. Features

1. The unique multi-filter chamber structure can realize online backwashing (filtering, draining and backwashing at the same time).

2. According to the water pressure of the system, the tank material can choose to use carbon steel or glass fiber reinforced plastic.

3. The regeneration time is short, the medicine is consumed, the water consumption is small, and there is no secondary pollution.

Four. technical parameter

1. Treatment effect:

①. Fluorine content: ≤1.0mg/L;

②. Turbidity of effluent: <3FTU;

③. Defluoridation capacity: 10g/kg filter material.

2. Water inlet requirements:

①. Fluorine content: ≤10mg/L;

②. Influent turbidity: <5FTU;

③. Alkalinity: ≤2mg/L;

④. pH value: 5.5-6.5 (5.5 is the best; when the pH value is more than 7, it is advisable to use sulfuric acid or CO2 to adjust the pH value to 5.5-6.5).

3. Working environment parameters

①. Working pressure: ≤0.4MPa;

②. Working temperature: 5-60℃ (special temperature can be customized).

4. Operating parameters

①. Working method: pressure type;

②. Operation mode: water flow from bottom to top, series (high fluorine content) or parallel;

③. Filter material particle size: 0.5-2.5mm;

④. Filtration speed: 2-6m/h (the larger the PH value and filter diameter, the lower the filtration speed);

⑤ Operation period: depending on the quality of the raw water, the minimum is not less than 8 hours;

⑥. Backwashing method: water washing, or air-water combined backwashing;

⑦. Backwash time: 10-15 minutes;

⑧. Water consumption for backwashing: 1-3%;

⑨. Backwash intensity: 18-25l/s·m2;

⑩. Backwash expansion rate: 30-50%;

⑾. Regeneration solution: 1%-2% aluminum sulfate or sodium hydroxide solution;

⑿. Regeneration time: 1-2h;

⒀. Regeneration intensity: 8-10L/m2·s;

⒁. Washing time: 8-10min.

five. working principle

1. Process flow

Adsorption and ion exchange → regeneration (backwashing, drug absorption, replacement, forward washing)

2. working process

①. Adsorption and ion exchange

The fluorine removal filter produced by our company, when groundwater with a fluorine content of less than 10mg/L passes through the filter, fluorine and fluoride are adsorbed on the surface of the adsorbent (active Al2O3) to generate insoluble fluoride, making the fluoride content of the effluent ≤ 1.0mg/L, up to the standard of drinking water.

②. Regeneration

When the effluent reaches a certain amount, the active Al2O3 will be saturated and the exchange capacity will be lost, and the operation must be withdrawn for regeneration. At this time, the effluent is provided by other tanks to ensure continuous effluent.

During regeneration, the filter material is first backwashed to remove impurities such as suspended solids that may be intercepted, and at the same time to loosen the active AL2O3. Then the liquid medicine is fed from the upper part of the tank, and the regeneration waste liquid is discharged through the drain valve. After the drug washing is over, the final positive washing process is carried out to completely remove the residual drug solution in the active AL2O3 layer.

The system can adopt manual and automatic control methods. The working status of each tank is in sequence: running → regeneration (backwashing, inhalation, replacement, forward washing) → running; when the equipment fails, it will automatically exit operation, start the regeneration program, and automatically put it into operation after regeneration. In order to ensure the need for production water, the control system prohibits simultaneous regeneration of the two equipment.

When the PH value of the raw water is not up to the requirement, CO2 gas shall be used to adjust the PH value of the raw water.

six. Specifications and dimensions

1. Dimensions

2. List of specifications and models

2. List of specifications and models

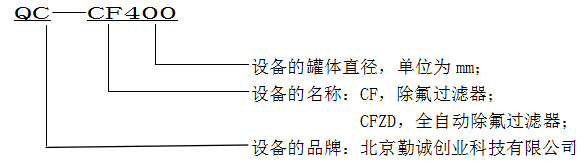

3. Model Description

3. Model Description

seven. Selection instructions

1. Equipment selection

①. The buyer needs to provide water quality report, usage, automation requirements, machine room size and other parameters in order to provide detailed equipment and filter material selection.

②. The primary or secondary treatment system can be selected according to the water quality, and the single or multiple parallel systems can be selected according to the water volume.

③. The process flow of fluorine removal should be determined according to the following conditions:

a. When the fluorine content of the raw water is ≤10mg/L, a single-stage treatment system is adopted;

b. When the fluorine content is greater than 10mg/L, use a secondary treatment system or a treatment system that uses reverse osmosis (or electrodialysis) as the main means of reducing fluoride.

2. device installation

①. The supplier shall provide the relevant operating data of the equipment (such as equipment weight, process flow chart, floor plan, foundation drawing, etc.), and the purchaser shall construct and construct the infrastructure of the equipment by itself based on the relevant operating data provided by the supplier. The concrete floor is poured smoothly, and the error does not exceed 10mm.

②. Calibrate the equipment smoothly, and the error shall not exceed 10mm, so that the equipment can run uniformly and stably.

③. Fill the filter material evenly, and install the filter material according to the design index and filter material specifications.

④. Install the supporting facilities of the equipment body such as pipelines and valves according to the design procedures, and check whether there is any leakage. If yes, perform emergency maintenance; if not, perform debugging.

⑤. Clean the filter element and filter material, open the filtered water and drain valve in turn, clean before operation, and wait until the cleaning water of the filter layer becomes clear. Check whether the equipment is running well.

⑥. Open the water inlet pipe and control the water inlet water volume so that the water inlet water volume meets the design flow rate. Take a clean water sample and open the clean water valve when the fluorine content is ≤ 1.0mg/L.

⑦. Debug the backflush pump, close the filter inlet and outlet pipe valves, open the backwash water inlet pipe and backwash outlet pipe valves. After the water discharged from the outlet pipe becomes clear, the backflush ends. Restart and operate normally.

- Previous Article: In addition to iron and manganese filter

- Next Article: Arsenic removal filter