one. Product Features

Fiber ball filter is suitable for deep purification treatment of surface water with turbidity not greater than 100mg/1 in rivers, rivers, lakes and reservoirs; it is also suitable for swimming pool recycling water treatment and direct filtration of wastewater after biological treatment, which is more suitable for water source comparison Water supply in tight water shortage areas makes the effluent water quality transparent, clean and hygienic. Meet the national drinking water quality standards.

two. Scope of application

Suitable for oilfield sewage, industrial sewage, heavy chemical solution, pretreatment of advanced sewage treatment, electronic pure water preparation, side filtration and waste water reuse, high-standard water for electricity, circulating cooling water for air conditioning, other high-precision water and swimming pool circulating water Wait for the occasion.

three. Features

High filtration precision, large processing capacity, fast filtration speed, low backwash intensity, and good filter regeneration effect.

Four. technical parameter

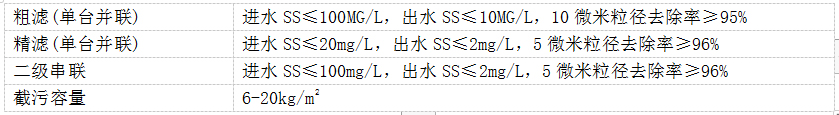

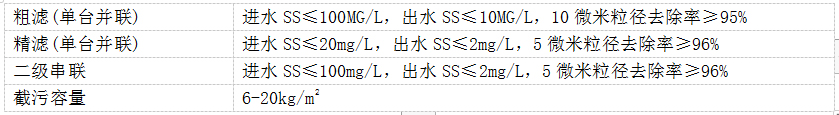

1. Treatment effect

2. Working environment parameters

2. Working environment parameters

①. Working temperature: 5-60℃ (special temperature can be customized);

②. Working pressure: 0.6MPa;

③. Inlet water pressure: ≥0.04MPa;

④. Backwash water inlet pressure: ≥0.15 MPa;

⑤. Pressure difference between inlet and outlet: ≤0.05MPa.

3. Operating parameters

①. Working method: pressure type;

②. Operation mode: water flow from top to bottom;

③. Filtration speed: 20-30m/h;

④. Operating cycle: 8-48h;

⑤. Backwashing method: air-water combination;

⑥. Water consumption for backwashing: 1-3%;

⑦. Backwash intensity: 5-15L/s·m2;

⑧. Backwash duration: 20-30min;

⑨. Backwash expansion rate: 40-50%.

five. working principle

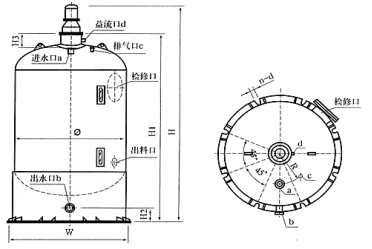

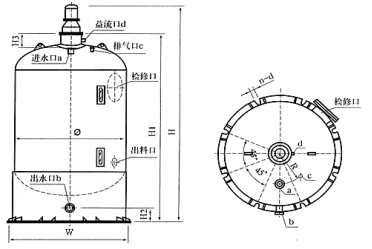

The fiber ball filter is mainly composed of a cylindrical pressure vessel, a support, a hole and a connecting pipe, and its working principle can be divided into two stages: filtration and backwashing. The raw water is added with a quantitative coagulant during filtration, and it is quickly mixed by the impeller of the water pump and then enters the equipment for purification and filtration. With the continuation of the filtration time, the retention on the filter layer gradually increases, and the head loss of the water flowing through the filtration will gradually increase. Backwash should be carried out when the water head reaches 5 meters. The method of backwash is to adjust the opening and closing of the valve so that the raw water enters the original water outlet, and the sewage is discharged from the sewage outlet of the water inlet. The gas should be reversed before the water backwash Flush, after the recoil lasts 5 minutes, enter the water flush again, the recoil can be put into normal operation state after the recoil.

six. Specifications and dimensions

1. Dimensions

2. List of specifications and models

2. List of specifications and models

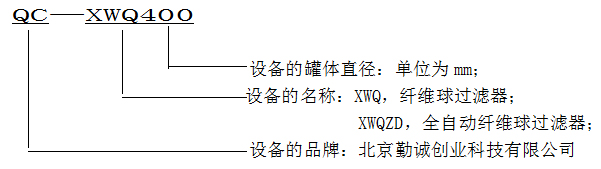

3. Model Description

3. Model Description

- Previous Article: Quartz sand filter

- Next Article: No Record