one. Product Features

As the latest water quality fine treatment equipment in the pressure filter, the modified high-efficiency fiber ball filter is a breakthrough of our company's fine filtration technology in oily sewage and other aspects, filling the gap in the field of oily sewage fine filtration. It can effectively remove oil and suspended solids in water, and has obvious removal effect on organic matter, colloid, iron, manganese, etc. in water.

The fiber ball filter material selected for this filter is made of special fiber yarn synthesized through a new chemical formula. Its main feature is that the fiber filter material is changed from lipophilic to hydrophilic through essential modification treatment. Solve the problem that the filtration accuracy of the granular filter material is limited by the particle size of the filter material. It is an updated product of granular filter media filtration equipment such as quartz sand.

two. Scope of application

1. It is widely used in circulating water side flow filtration, advanced domestic water treatment, boiler feed water treatment, reverse osmosis pre-filtration, and sewage reuse filtration.

2. It is suitable for the coarse, medium and fine filtration of oilfield oily sewage reinjection and the efflux treatment of oilfield and refinery sewage;

3. It is suitable for recycling and filtering treatment of various industrial circulating water and domestic water and waste water such as steel, thermal power, shipbuilding, papermaking, medicine, chemical industry, textile, food, beverage, tap water, swimming pool and so on.

three. Features

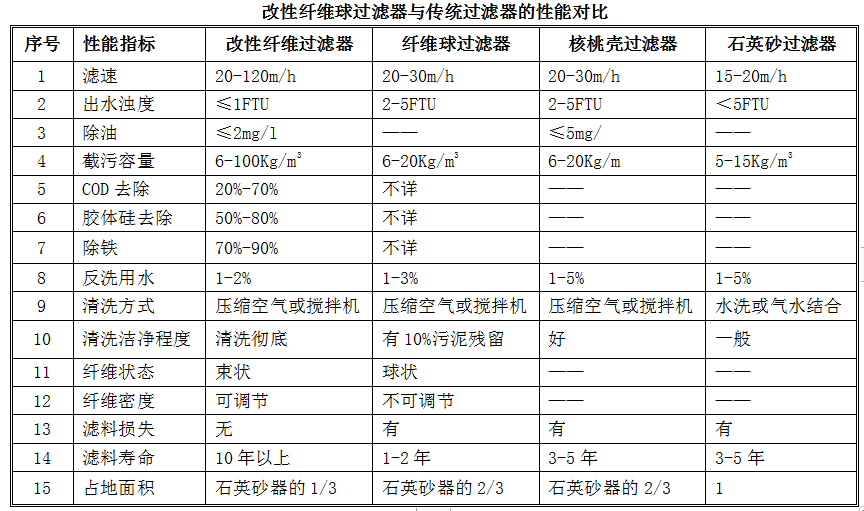

Four. technical parameter

1. Treatment effect

five. working principle

When filtering, the raw water is added with a quantitative coagulant, which is quickly mixed by the impeller of the water pump, and then enters the equipment for purification and filtration.

1. The mechanism of modified fiber ball to remove oil and machinery is: direct interception, inertial interception and electrochemical adsorption;

2. The principle of deep bed filtration, vertical tank, backwashing with mechanical agitation, can be operated manually and automatically;

3. When filtering, sewage flows from top to bottom on the filter layer, oil and suspended solids are intercepted, and most of the dirt is removed;

4. During backwashing, clean water rinses the filter material from bottom to top, while stirring while flushing, the dirt intercepted by the filter material is gradually cleaned.

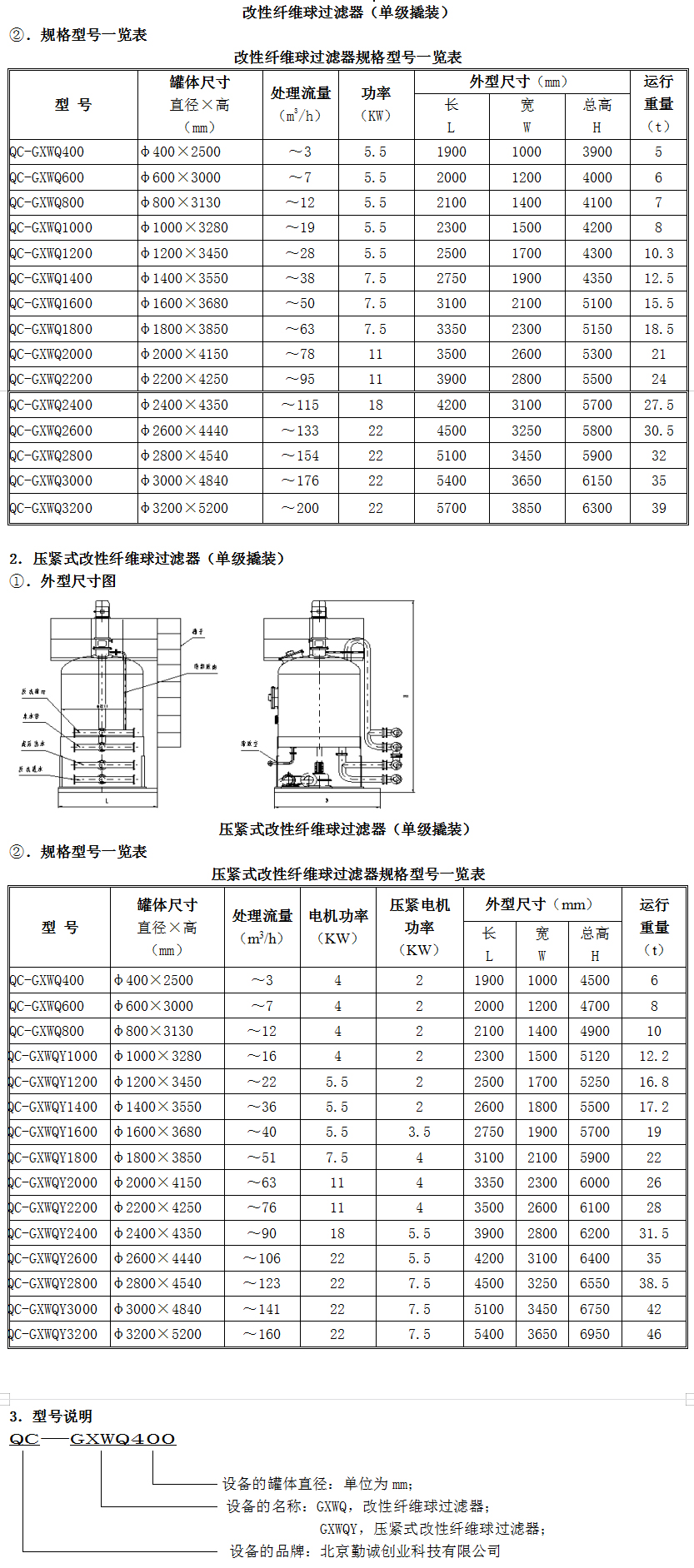

In response to some high-precision processing requirements, in order to prevent the filter layer from not being fully compressed and to improve the internal structure of the filter equipment, we designed a filter material compression device to move the stirring mechanism from the upper part of the filter tank to the bottom. The pressing device is located in the upper part of the filter tank.

When working, the filter material pressing device is activated, the pressing plate descends to a certain position to compress the filter material, and the sewage flows from top to bottom through the filter layer through the filter; when the backwashing starts, the filter material pressing device starts and the pressing plate moves, The backwash pump starts, the backwash water flushes the filter layer, and the mixer starts. In this way, the pore structure of the filter layer is more stable and compact, which is more conducive to the removal of suspended solids, and ensures the stability of the filtration accuracy of the fiber ball filter.

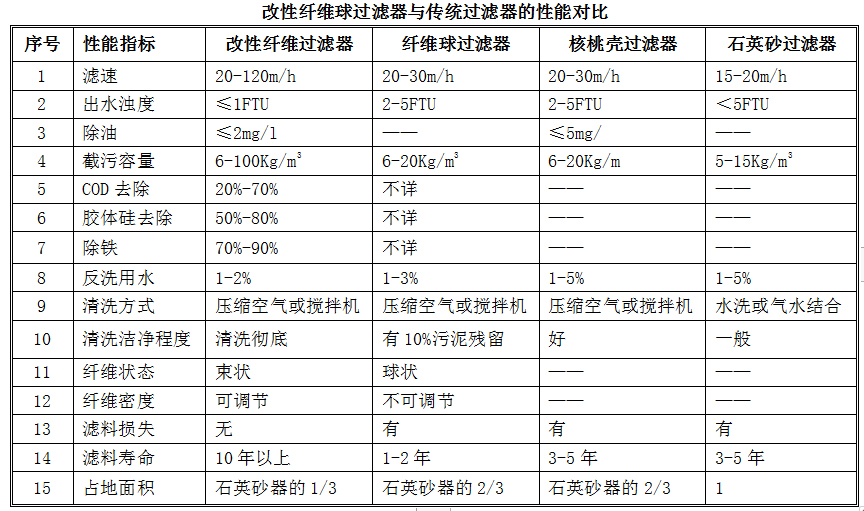

six. Specifications and dimensions

1. Modified fiber ball filter (single-stage skid mounted)

①. Dimensions

- Previous Article: Activated carbon filter

- Next Article: Fiber bundle filter