one. Product Features

The fiber bundle filter is a pressure-type fiber filtration equipment with advanced structure and excellent performance. It uses polymer polypropylene fiber bundles as the filter material. The diameter of the filter material can reach tens of microns or even several microns, reaching the micron level.

Compared with the granular filter material, the fiber bundle filter material has the advantages of large specific surface area and low filtration resistance, which solves the problem that the filtration accuracy of the granular filter material is limited by the particle size of the filter material. It is an updated product of quartz sand and other particulate filter equipment.

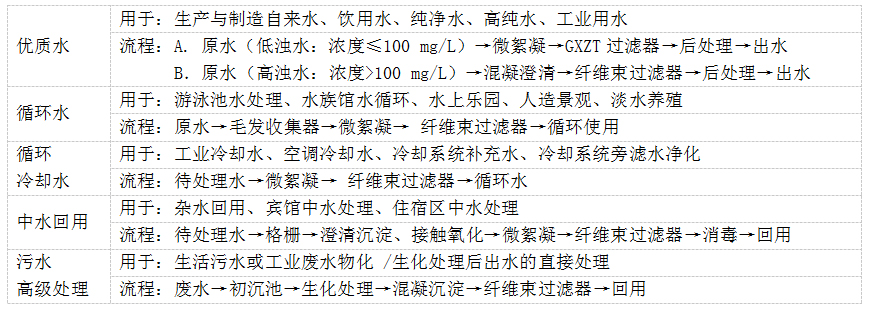

two. Scope of application

three. Features

Four. technical parameter

1. Treatment effect

①. Influent suspended matter: <50mg/L, effluent suspended matter: <5mg/L;

②. Influent suspended matter: <20mg/L, effluent suspended matter: <1mg/L;

③. Iron content of influent: <15mg/L, iron content of effluent: 0.3 1mg/L;

④. Sewage interception capacity: 5-15Kg/m3 (filter material).

2. Working environment parameters

①. Working temperature: 5-60℃ (special temperature can be customized);

②. Working pressure: ≤0.6MPa;

③. Inlet water pressure: ≥0.04MPa;

④. Backwash water inlet pressure: ≥0.15 MPa;

④. Pressure difference between inlet and outlet: ≤0.05MPa.

3. Operating parameters

①. Working method: pressure type;

②. Operation mode: water flow from top to bottom;

③. Filtration speed: 25-35m/h;

④. Operating cycle: depending on the turbidity of the incoming water, the minimum is not less than 8 hours;

⑤. Backwashing method: air-water combination;

⑥. Water consumption for backwashing: 1-3%;

⑦. Washing strength: 4-15l/s·m2;

⑧. Air pressure: 0.05-0.1MPa (Roots blower or oil-free air compressor can be used);

⑨. Air intensity: 40-60 L/m2·s;

⑩. Backwash duration: 20-50min (depending on the capacity of interception).

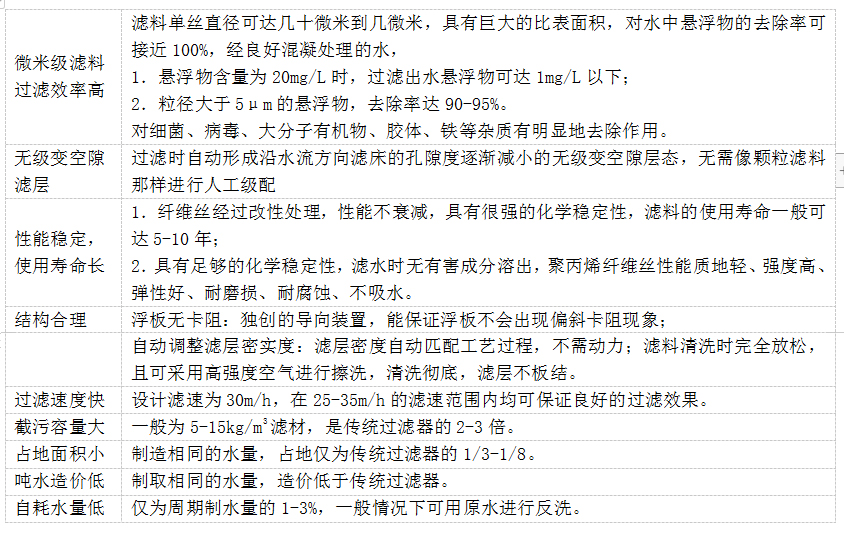

five. working principle

The equipment is composed of fixed perforated plates, fiber bundles, movable perforated plates, and air distribution devices. One end of the fiber bundle filter material is fixed on the fixed porous plate, and the other end of the filter material is provided with a self-service adjusting device that can change the fiber density. The device is provided with a guide member to prevent jamming.

During operation, the equipment enters water from the upper part and discharges water from the lower part. At this time, under the action of water flow and gravity, the self-service fiber density adjustment device pushes the fiber filter bed to run downwards, the fiber filter layer is compressed, and its bulk density gradually increases along the direction of the water flow, so that the filter layer flows along the water. The direction of the porosity gradually decreases from larger to smaller, and the corresponding filter layer pore diameter and pores gradually decrease, thus forming a particularly ideal variable-porosity deep filtration state. The filtration process includes both horizontal deep filtration and vertical deep filtration, thereby effectively improving the filtration accuracy.

When the filter layer is contaminated and needs to be cleaned and regenerated, the cleaning water passes through the fiber filter bed in the opposite direction. Under the action of the backwash water flow and the cleaning air, the self-service fiber density adjustment device drives the fiber filter bed to move upward to stretch the fiber filter material upwards. , To achieve a loose state, through the air-water mixing cleaning technology, during the bubble gathering and water washing process, the fiber filter material is in a state of continuous shaking in the longitudinal direction, so that the fiber filter material is cleaned very thoroughly, so as to achieve the ideal cleaning effect.

six. Specifications and dimensions

1. Dimensions

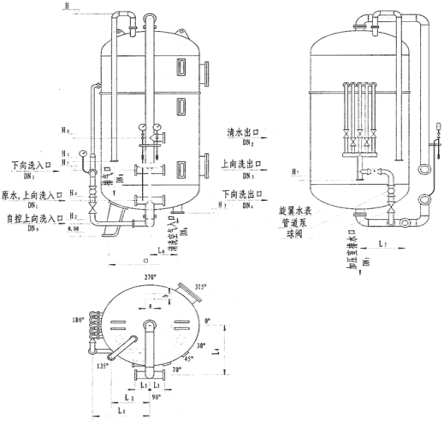

2. List of specifications and models

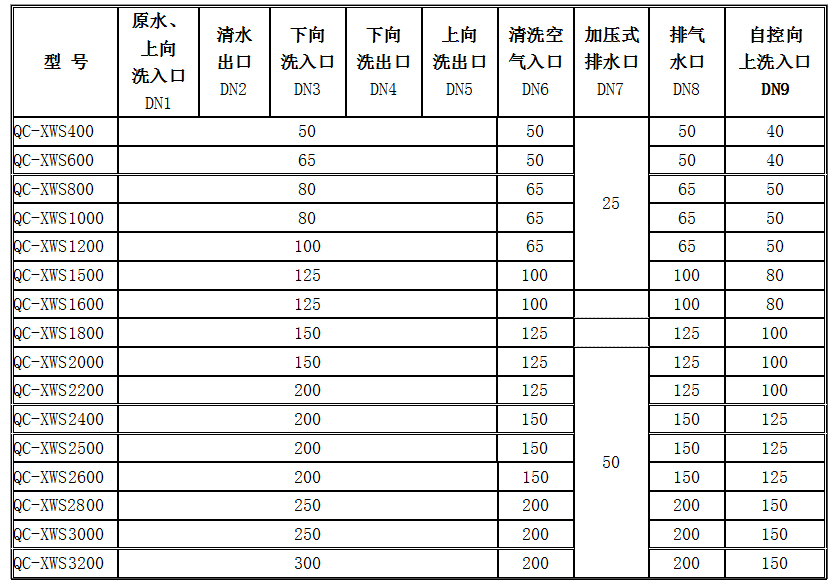

List of fiber bundle filter interface size

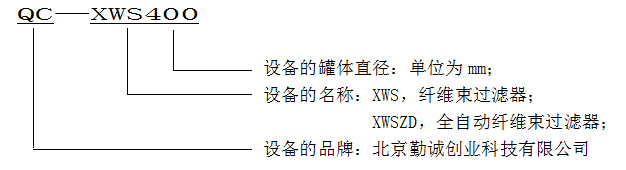

3. Model Description

seven. Selection instructions

1. Equipment selection

①. The buyer must provide detailed water quality test reports, water quality usage, automation requirements, machine room size and other basic parameters, so that the supplier can provide detailed selection;

②. The water quality before filtration is surface water that has undergone coagulation treatment;

③. When the water quality before filtration is groundwater containing iron and manganese, aeration treatment should be carried out first;

④. Designed filtration rate: 30m/h in addition to suspended solids, 20m/h in addition to iron and manganese; according to process conditions and user requirements, the maximum design flow rate can reach 40m/h;

⑤. Optional supporting equipment: ① valve; ② Roots blower.

- Previous Article: Modified fiber ball filter

- Next Article: Walnut shell filter