The ceramic step ring absorbs the characteristics of the short Raschig ring, and also changes the habit of equalizing the ring height and diameter of the filler, reduces the height of the ring, reduces the thickness of the material, and adds a flanging on the side. end of the ring. Because the side ends of the step ring increase the flanging, not only the mechanical strength of the packing ring can be increased, but also because the symmetry of the packing structure is destroyed, the orientation probability of the packing is increased when the packing is put. Also, due to the influence of the flanging, the contact between the annular gaps of the fillers during the packing is changed from the linear contact to the point contact. In this way, not only the gap between the filler particles is increased, and the resistance of the gas passing through the filler layer is reduced, but these contact points can also be the convergence and dispersion points of the liquid flowing along the surface of the filler, thereby promoting the surface renewal of the liquid film, which is beneficial to Improved packing mass transfer efficiency. Therefore, the performance of the step ring is further improved than the Pall ring.

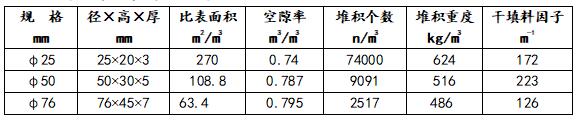

>>Performance parameters

- Previous Article: Cross diaphragm ring

- Next Article: Saddle ring