The active ceramic ball is a new type of reactor supporting packing independently developed by the company. It is made by adding a small amount of transition metal oxide to the inert ceramic ball composition. It not only has the characteristics of high temperature resistance, high pressure and high mechanical strength of the inert ceramic ball, it plays the role of filtering, dispersing vapor and liquid, covering and supporting the catalyst, but also has certain catalytic activity. It plays a role in the process of olefin saturation, desulfurization and denitrification. Promoting catalysis. In the hydrogenation reactor of distillate oil hydrofining, hydrocracking, reforming pre-hydrogenation and benzene hydrogenation, the top of the catalyst bed is filled with active ceramic balls, so that the olefins in the secondary processing feed oil can be initially hydrogenated. Thereby reducing the coking of the catalyst; filling the active ceramic ball at the bottom of the catalyst bed can remove the mercaptans produced in some reaction processes. The use of active ceramic balls can not only effectively improve the space utilization of the reactor, but also protect the catalyst from being poisoned and sintered in a certain procedure, thereby prolonging the service life of the catalyst.

>>Specifications and models

There are 12 sizes of active ceramic balls, which are divided into Φ3, Φ6, Φ8, Φ10, Φ13, Φ16, Φ20, Φ25, Φ30, Φ38, Φ50, Φ60 according to their nominal diameters. Products of other models and specifications can be produced according to user requirements.

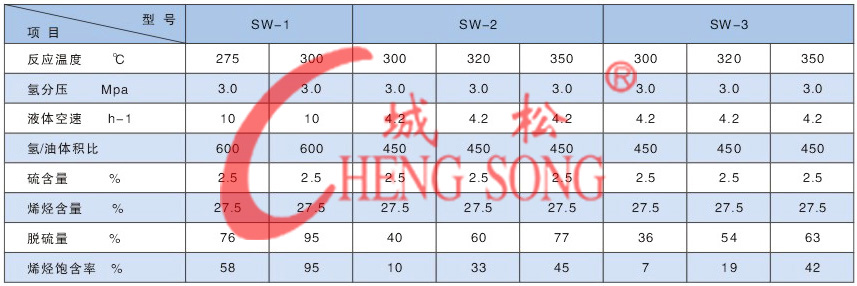

>>Main technical indicators

>>Physical properties

>>Executive standards

People's Republic of China Chemical Industry Standard HG/T3683.2-2000 "Industrial Porcelain Ball-Active Porcelain Ball"

- Previous Article: open hole porcelain ball

- Next Article: Inert alumina ceramic ball