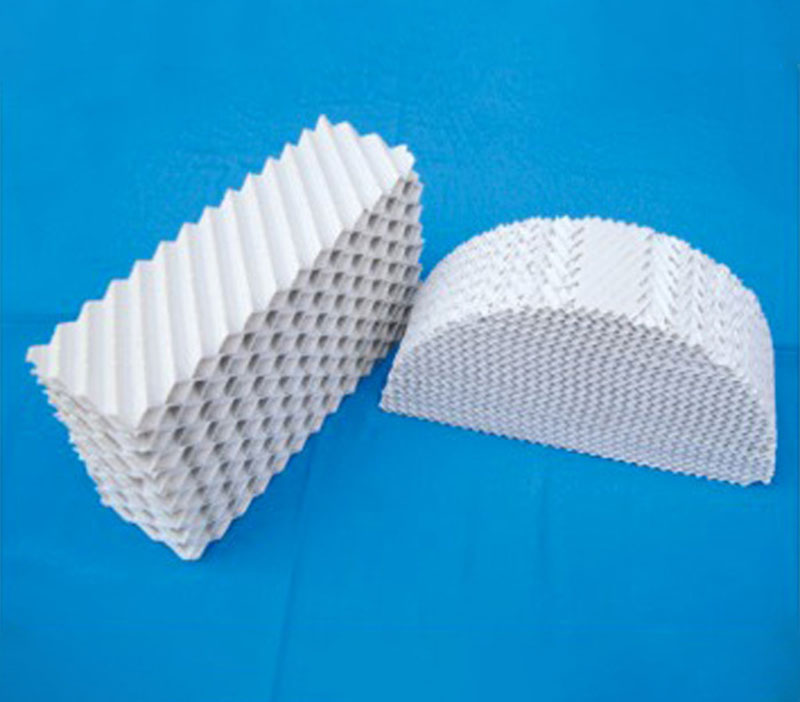

Ceramic corrugated packing is composed of many packing units with the same geometric shape. It has the advantages of large flux, low resistance, high efficiency, corrosion resistance, high temperature resistance (up to 1000 degrees Celsius), large operating flexibility, and insignificant amplification effect. It is especially suitable for the separation process of high temperature and corrosive media. The operating pressure is between 0.1-500Kpa and the application effect is good. Distillation of halogenated organic compounds; distillation and absorption of corrosive mixtures with strict requirements on pressure drop and theoretical plate number; sulfuric acid absorption, nitric acid concentration and gas purification in chemical fertilizer plants and other towers containing a large amount of acid media.

>>Excellent performance

●Large circulation, the new tower design can reduce the tower diameter, and the transformation of the old tower can greatly increase the processing capacity;●High separation efficiency. It has a much larger specific surface area than random packing;

●The pressure drops. Can save a lot of energy;

●The operation flexibility is large, and the amplification effect is not obvious;

●Suitable for various tower diameters;

●Strong resistance to acid, alkali, especially H2S, naphthenic acid chloride ion.

>>Physical and chemical properties

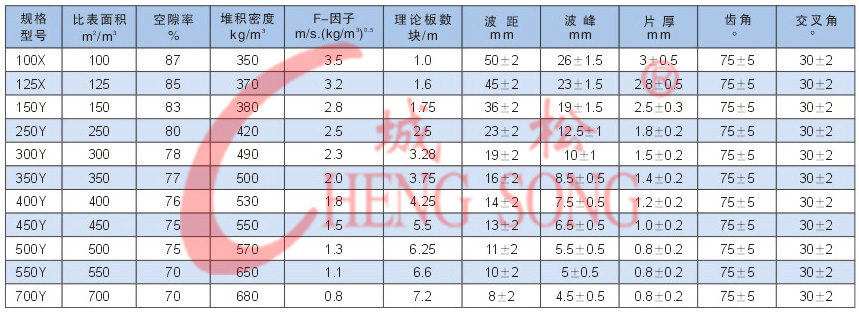

>>Characteristic data

The models of ceramic corrugated packing are 100-750X/Y, X and Y represent the inclination angle of the corrugation at 30° and 45° respectively. The Arabic numerals in front of X and Y are the specific surface area of the corrugated packing. The diameter of the packing plate is 100-8000mm, and it can also be designed and manufactured according to user requirements.

- Previous Article: Ball ring

- Next Article: Activated alumina