(1). Product features

AA open-hole ceramic ball is a new product developed by our company on the basis of inert alumina ceramic ball. Increase the specific surface area and porosity, thereby increasing the dispersion and flux, and reducing the resistance of the system. It can be widely used in petroleum, chemical and natural gas industries to replace inert alumina ceramic balls as catalysts and covering supporting fillers.

The product won the national patent in 1995, the first prize of provincial outstanding new product in 1996, and the provincial patent product excellence award in 1997. Since the product was put on the market, it has been favored and praised by users. It has been proved by users that in the same reactor and reactor under the same operating conditions, compared with the original covering support material, the vapor-liquid distribution is more uniform, the flow rate is significantly increased, the system resistance is significantly reduced, and the catalyst does not agglomerate , Does not burn, thus prolonging the service life of the catalyst.

(2). Physical and chemical properties

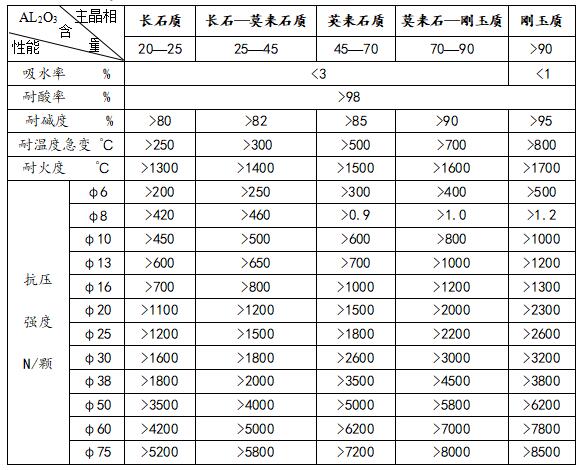

Specifications: According to its diameter, the specifications of AA open-hole ceramic balls are divided into twelve types: φ6, φ8, φ10, φ13, φ16, φ20, φ25, φ30, φ38, φ50, φ60, φ75, etc.

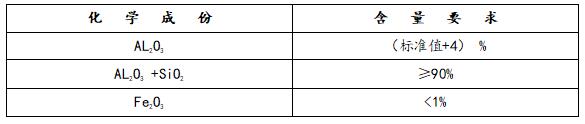

Varieties: According to the AL2O3 content of the AA open-pored ceramic balls, from 20% to 95%, every 5% is a grade, a total of 16 varieties, and can also be produced according to the specifications and AL2O3 content required by users.

(5). Ordering instructions

①Users should study the basic conditions of the device together with our personnel when placing an order, including the size of the reactor, operating conditions, temperature, etc.

②When ordering, the specification, model, number of holes and whether reinforcement ribs are needed should be mentioned.

③Natural close-packed packing should fully consider the pile ratio, so the user and our personnel must determine the quantity according to the actual packing volume when ordering.

- Previous Article: Wide-side porous net nest catalyst protective agent

- Next Article: Active porcelain ball