(Independent research and development of patented products)

The wide-side porous mesh tank catalyst protective agent is a new type of catalyst proppant and protective agent in petrochemical hydrogenation, hydrogen production, reforming and other equipment. This product is our company adopts a unique structural design on the basis of comprehensive foreign technology. The proppant is made into a porous wide-side mesh slot. When it is placed on the side, the bottom or top is carried by the wide-side porous mesh slot. , Increase the load capacity and improve the side pressure strength; the size design of the 8 wide-side porous mesh groove and the axial opening can increase the porosity of the support medium, thereby reducing the pressure drop of the catalyst bed. Comparing this proppant with similar products, the results show that compared with traditional proppants, the wide-side porous mesh groove catalyst protectant has a 30% increase in strength and an increase in porosity of more than 45%. It solves some of the defects encountered by general catalyst inert proppants and other support materials. For example, the commonly used proppants are cylindrical, annular, etc., but the annular and cylindrical supports have high strength but low porosity, small specific surface area, and bed resistance. Large; the annular carrier has a high porosity but low strength and is easily damaged, which affects the use efficiency of the catalyst and the device. At the same time, the product is resistant to high temperatures, ceramics can withstand temperatures up to 1360C, and corundum can withstand high temperatures up to 1680°C.

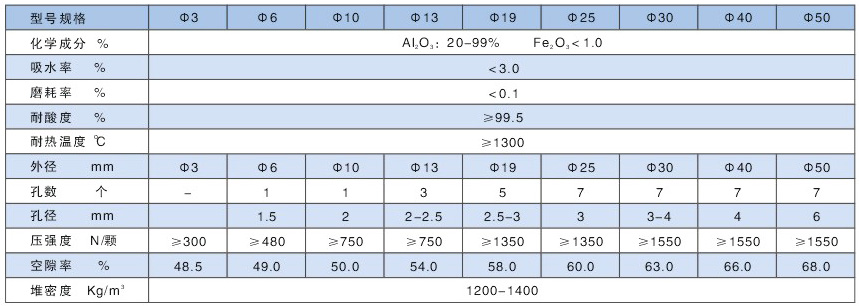

>>Main performance indicators

>>Product Application

The wide-side porous mesh slot catalyst protective agent is mainly used in all occasions in petroleum refining, environmental protection, hydrogen peroxide, hydrogen production, coal chemical industry, etc. instead of inert alumina proppant, inert ceramic balls, and open-pored ceramic balls. details as follows:

1. Fixed-bed reactors for hydrogenation, hydrogen peroxide, hydrogen production, catalytic reforming, product refining, and light hydrocarbon processing in petroleum refining.

2. Ethylbenzene, styrene, polypropylene, acrylonitrile, PTA and other petrochemical industries and synthetic ammonia, hydrogen peroxide and other inorganic chemicals.

- Previous Article: High alumina ceramic ball (porcelain pillar)

- Next Article: open hole porcelain ball