(1 Overview

Inert alumina ceramic balls are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as the covering support material and tower packing for the catalyst in the reactor. It has the characteristics of high temperature and pressure resistance, low water absorption, and stable chemical properties. It can withstand the corrosion of acids, alkalis and other organic solvents, and can withstand temperature changes during the production process. Its main function is to increase the gas or liquid distribution points, support and protect the active catalyst with low strength.

The product developed by our company won the Jiangxi Province Excellent New Product Award and the Science and Technology Progress Award in 1988, and was listed on the National Excellent New Product List in the same year. In the 1990s, it was awarded the National Science and Technology Achievement Certificate. Gold award. For several years, it has been awarded the product recommendation certificate of Sinopec Corporation. Since the product was put on the market, users from all walks of life have reported that its performance and effects are comparable to imported products, and some technical indicators are even higher than similar foreign products.

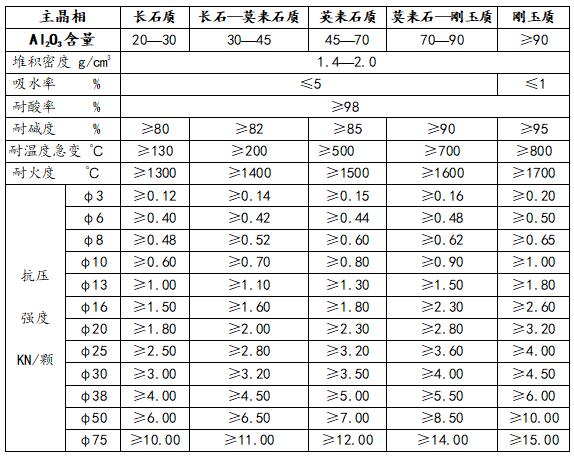

(2). Physical properties

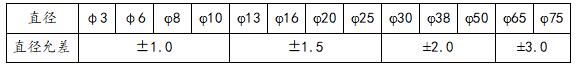

①. Specification and diameter tolerance

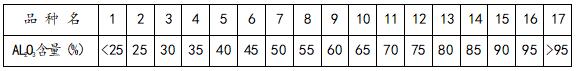

②. Variety

According to the AL2O3 content of the inert alumina ceramic balls, starting from 25%, every 5% isolation is a grade, which is divided into 17 varieties;

① The user should introduce the basic conditions of the device in detail when placing an order, including reactor size, working temperature, etc.;

②The specification, model, and total content of aluminum and silicon components of the required product should be mentioned when ordering;

③Because the inert ceramic balls are packed in a natural close pile in the reactor, the user should determine the quantity with our personnel according to the actual filling volume when placing an order, and 15-20% of the margin should be considered.

- Previous Article: Active porcelain ball

- Next Article: No Record