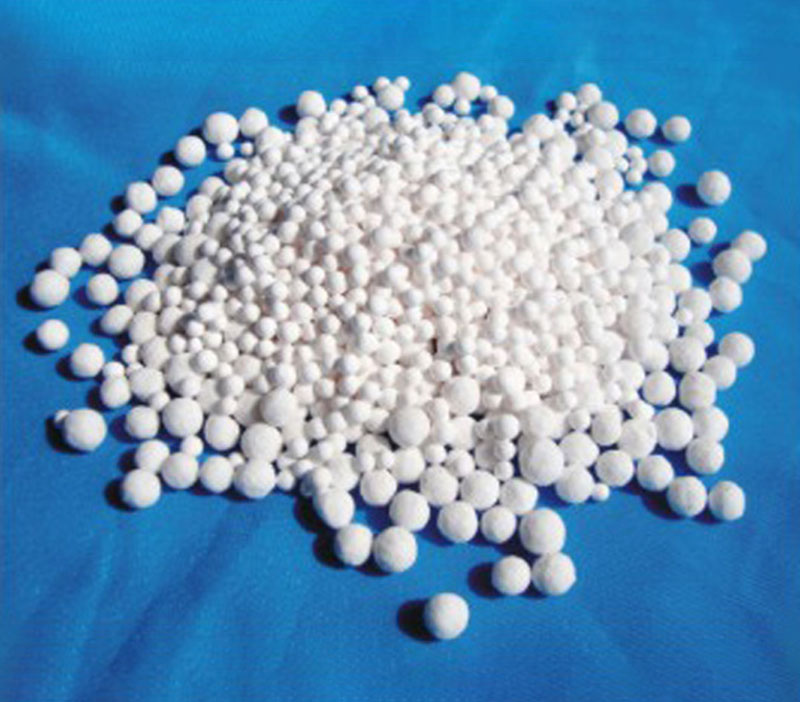

The microporous ceramic ball, also known as proppant, is an inert ceramic ball with 20-30% micropores with adsorption effect. Therefore, in addition to supporting and covering the catalyst and dispersing vapor and liquid as the inert ceramic ball, it can also absorb and filter impurities in the oil. The impurities in the oil are in the form of particles, colloids, asphaltenes, and heavy metals. Although some of these impurities can be filtered out after passing through the raw material filter, there are still a considerable part (such as particulate impurities and particles less than 25 μm). Iron ions) still cannot be filtered out. If the porous ceramic ball is loaded on the top of the reactor, the unfiltered impurities in the raw materials can be adsorbed in the pores, thereby protecting the catalyst and extending the operation period of the device.

According to the types of impurities in the raw materials processed in the hydrogenation, hydrogen production and reforming devices, the content and particle size are different, users can choose porous ceramic balls with different pores and numbers of holes, and can also carry molybdenum, nickel, cobalt and other activities according to needs. Ingredients to prevent carbon deposition and coking and poisoning of the catalyst.

>>Technical Index

- Previous Article: Microporous carrier

- Next Article: High alumina ceramic ball (porcelain pillar)